It has been a little over six months since I launched the Kokuin website. As my first products for sale, I had made some coasters and napkin sets using textile paints. It had taken me a few months to get all of that ready, preceded by several trial pieces and some that I had to reject because of small errors. I was slower at sewing too, mainly because I didn’t want to make mistakes. Sewing at the slowest setting felt like an endurance sport sometimes! I was trying to be mindful of the materials I had and did not want to waste more than what was absolutely unavoidable. Nevertheless, I did make mistakes (which I couldn’t offer for sale, of course) and had to start over. I have kept all of my trial and error pieces – they are helpful and sometimes amusing markers of my learning experience.

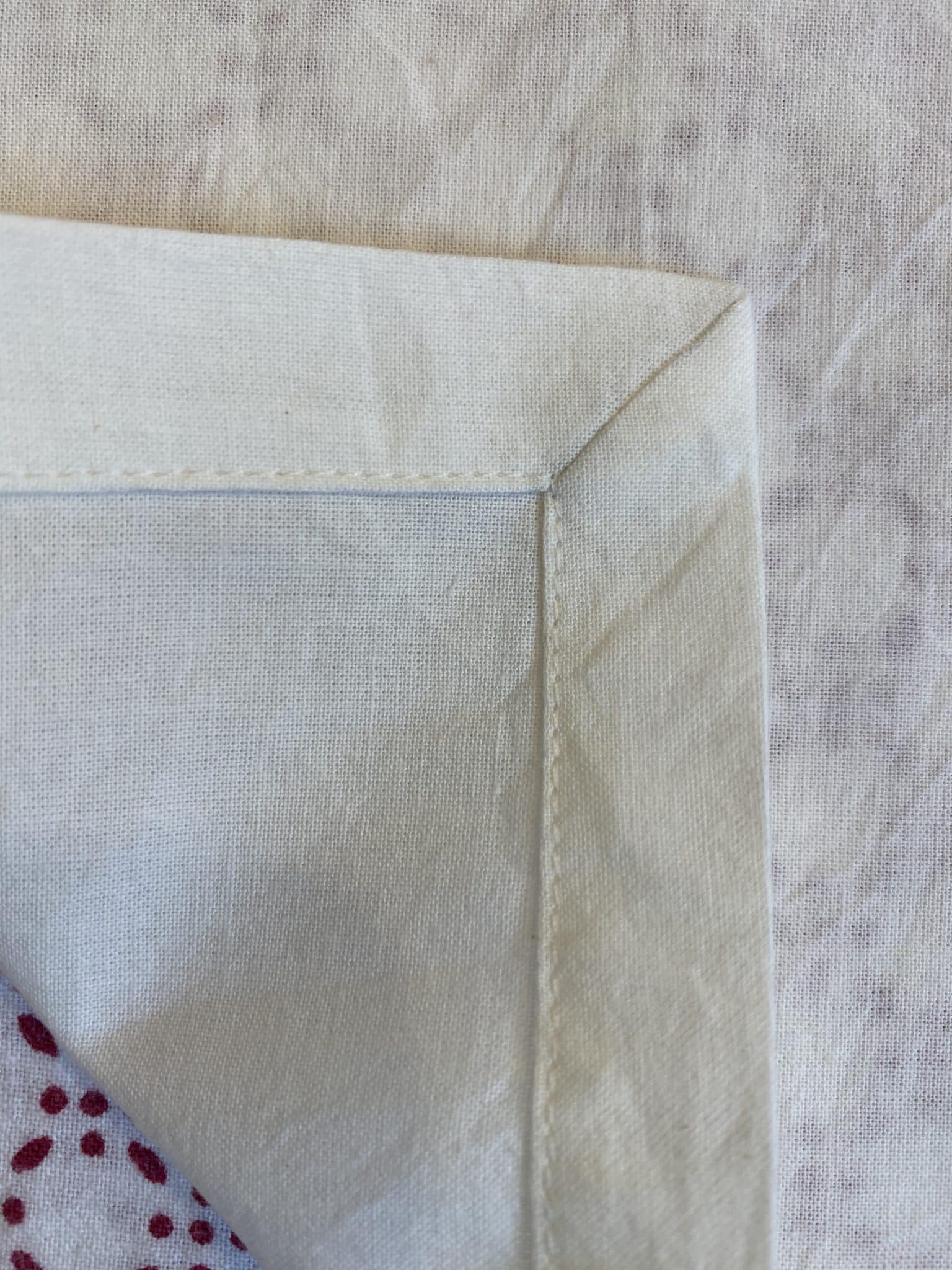

As I was getting through that process, I started thinking about using dyes in addition to paint. I had learnt that dyes form a molecular bond with the fabric, making it more long-lasting than paint. It seemed rather daunting though. It was a new, more involved process and additional materials had to be purchased. But the allure and the challenge were too much to resist. So I started learning the dyeing process as well. It was a steeper learning curve. Some pieces did not come out the way they were meant to. In others, there were errors in printing. Frustrating as it was, I kept at it, trying one method after another. Over several trials (and over several months), I learnt better methods of sewing, dyeing and printing – improved proportions of dye: urea water: print paste, how to get a crisp print repeatedly without clogging up the grooves on the woodblock, how much pressure to apply when using the block (when to press and when to smack the block), which time of the day is best to start the printing process with dyes so that I can print in the best conditions, how to keep dyed fabric warm and moist for longer so that the dye will bond better with the fabric, how to wash the dyed fabric so that only the excess will wash off, and of course how to sew faster and better. A useful tip that I learnt a couple of months ago was to steam press the hem just before the final hemstitching – that helps you get the neatest mitered corners! I will also be trying out a new method of keeping the newly dyed fabric warm without overheating the entire room, which is what I had been doing so far. Fabric is my biggest expense, and over the course of the months, I have researched and found sources of fabric that sell more reasonably priced, better quality and ethically produced material. These small steps add up to improving the speed and efficiency of production which in turn will reflect in the pricing of the products (in a positive way for the customers). There is always room for improvement, and so I am sure there will be more updates which I’ll be happy to share with you.